Products

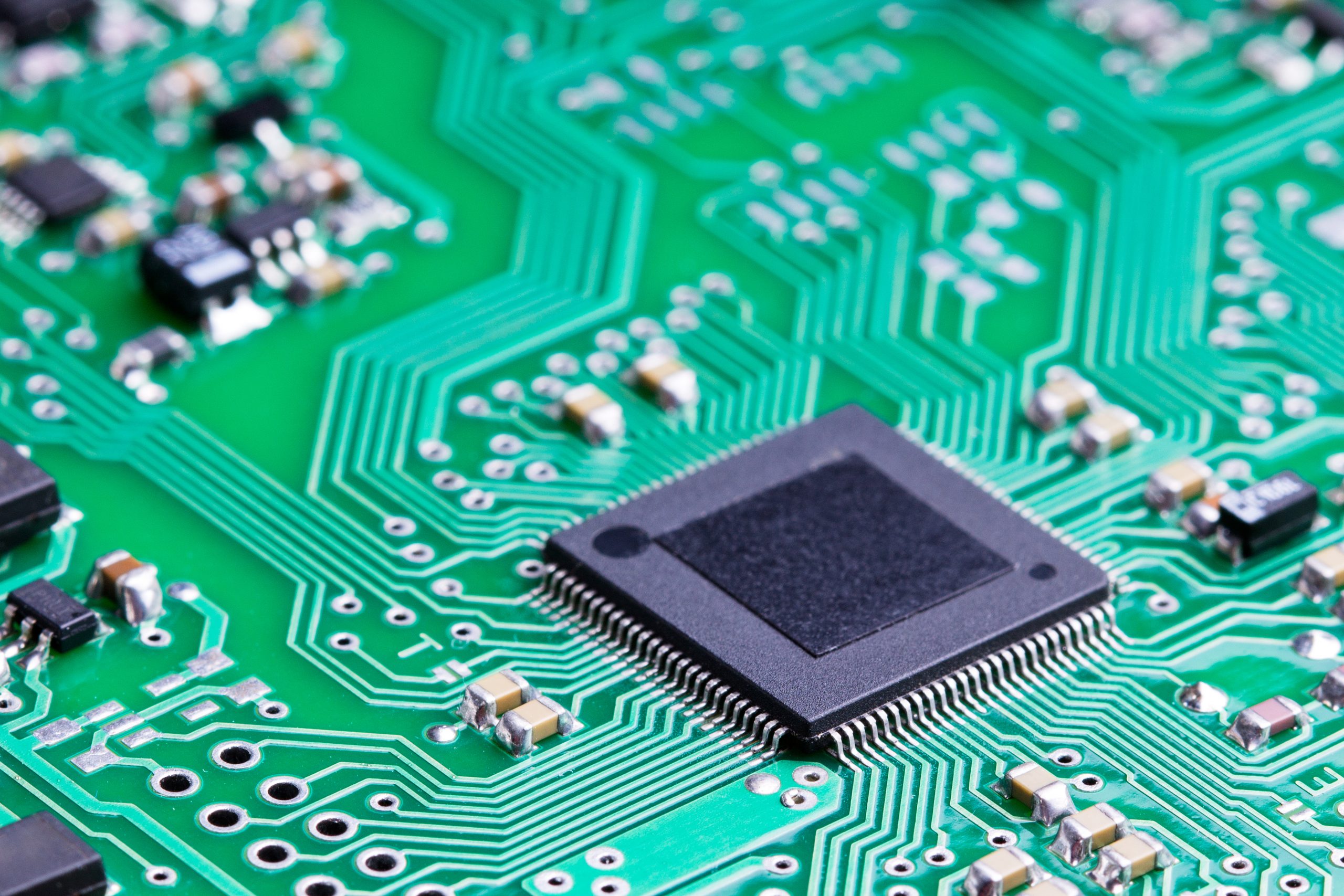

PCB products

There are various methods for the hobbyist to make PCB boards. I use the toner transfer method because it is cheap and requires relatively little setup or equipment. You need access to a laser printer or photocopier, an iron, and you’ll need an etching solution.

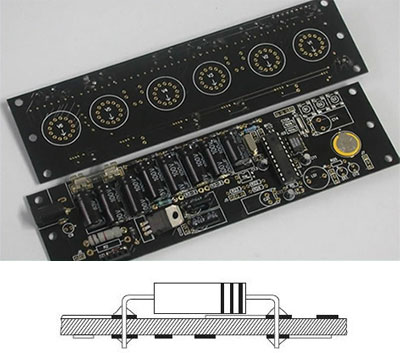

PCB Single Side

Single-sided PCB means that wiring is available only on one side of the insulating substrate. The side which contains the circuit pattern is called the solder side whereas the other side is called the component side.

- Power supplies.

- Relays (automotive and industrial)

- Timing circuits.

- Sensor products.

- LED lighting.

- Radio and stereo equipment.

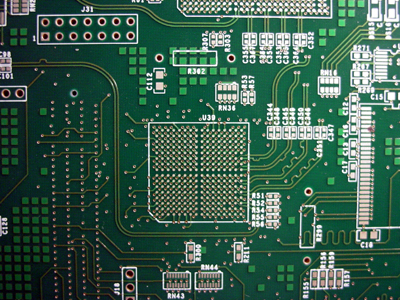

PCB Double Side

Double-sided printed circuit boards have wiring patterns on both sides of the insulating material, i.e. the circuit pattern is available both on the components side and the solder side. Obviously, the component density and the conductor lines are higher than the single-sided boards.

- Double-sided board with plated through-hole connection (PTH)

- Double-sided board without plated through-hole connection (non-PTH)

Multilayer

A multilayer PCB board is used in situations where the density of connections needed is too high to be handled by two layers or where there are other reasons such as accurate control of line impedances or for earth screening.

- Wherever weight and volume savings in interconnections are the overriding considerations

- When the complexity of interconnection in sub-systems requires complicated and expensive wiring or harnessing

- When frequency requirements call for careful control and uniformity of conductor wave impedances with minimum distortions and signal propagation, and where the uniformity of these characteristics from board-to-board is important

- When coupling or shielding of a large number of connections is necessary

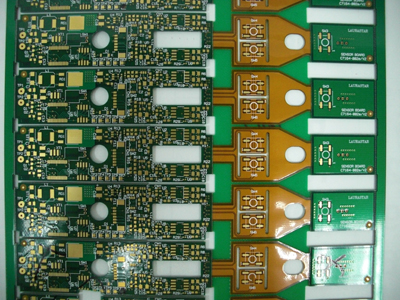

Flexible

Flexible electronics, also known as flex circuits, is a technology for assembling electronic circuits by mounting electronic devices on flexible plastic substrates, such as polyimide and PEEK Film. Additionally, flex circuits can be screen printed silver circuits on polyester.

- Tightly assembled electronic packages, where electrical connections are required in 3 axes, such as cameras (static application).

- Electrical connections where the assembly is required to flex during its normal use, such as folding cell phones (dynamic application).

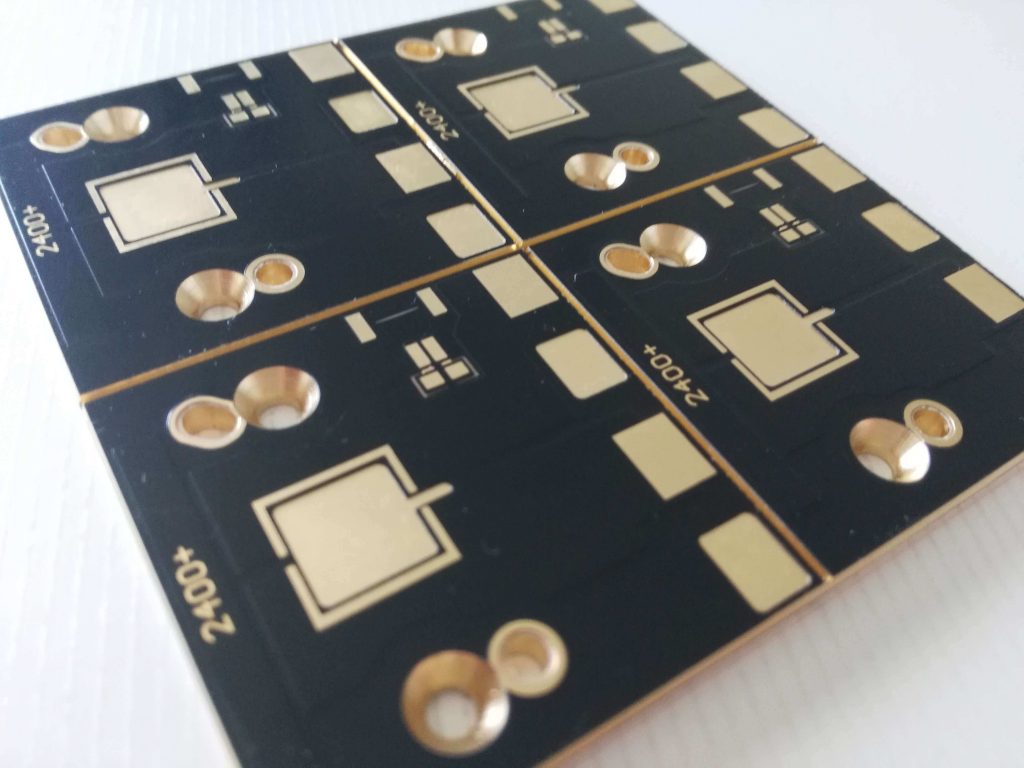

Metal Core PCB

As Metal Core PCB means the base material for PCB is metal, but not normal FR4/CEM1-3, etc, and currently what the metal used are Aluminum, Copper alloy. MCPCBs are used instead of traditional FR4 or CEM3 PCBs because of the ability to efficiently dissipate heat away from the components. This is achieved by using a Thermally Conductive Dielectric Layer.