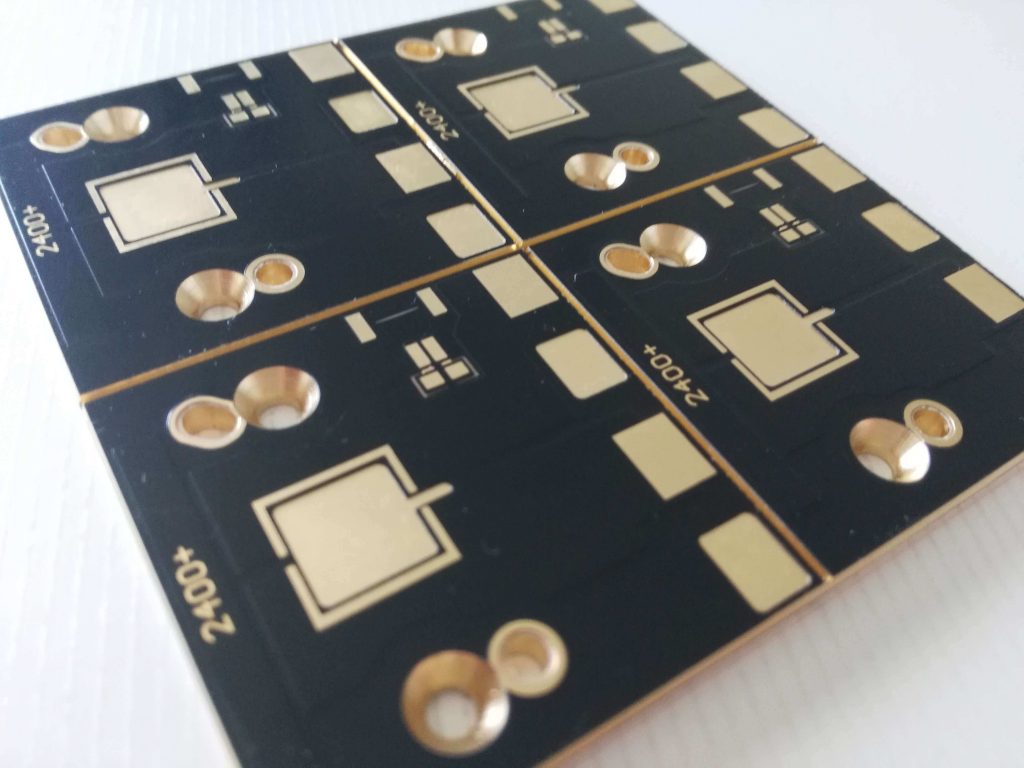

Metal Core

Metal Core PCB

As Metal Core PCB means the base material for PCB is metal, but not normal FR4/CEM1-3, etc, and currently what the metal used are Aluminum, Copper alloy. MCPCBs are used instead of traditional FR4 or CEM3 PCBs because of the ability to efficiently dissipate heat away from the components. This is achieved by using a Thermally Conductive Dielectric Layer.

The main difference between a FR4 board and MCPCB is the thermally conductive dielectric material in the MCPCB. This acts as a thermal bridge between the IC components and metal backing plate.

Heat is conducted from the package through the metal core to an additional heat sink. On the FR4 board the heat remains stagnant if not transferred by a topical heatsink. According to Avago’s white paper a MCPCB with a 1W LED remained near an ambient of 25C, while the same 1W LED on a FR4 board reached 12C over ambient.